DESCRIPTION

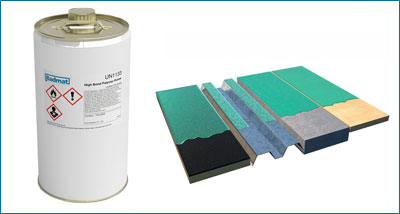

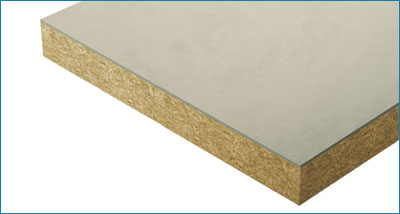

FOAMGLAS® INVATHERMTM has been engineered to meet the demand for a Class A1* inverted roof insulation board for use on roofs, roof terraces and balconies. Suitable for use with any inverted roof waterproofing membrane including hot melt, liquid applied or reinforced bitumen membrane. Consisting of cellular glass with a pre-applied inorganic coating# on the topside both the core material FOAMGLAS® INVATHERMTM is manufactured from specially graded recycled glass (≥ 60%) and natural raw materials which are available in abundant supply (sand, dolomite, lime). Totally inorganic FOAMGLAS® INVATHERMTM contains no ozone depleting propellants, flame resistant additives or binders, VOC or other volatile substances.

*Class A1 to BS EN 13501-1, sometimes referred to as ‘non-combustible’

#As product is made from natural materials the colour cannot be guaranteed and can vary in batches.

SUITABLE APPLICATIONS

FOAMGLAS® INVATHERMTM is suitable for use in all forms of inverted roof applications including on Specified Attachments. Suitable applications include projecting open balconies, projecting enclosed balconies, recessed open balconies, recessed enclosed balconies, roofs, roof terraces, enclosed balconies over heated space and insulated walkways.

NHBC Requirements

For Inverted Warm Roof systems, the FOAMGLAS® INVATHERMTM system is acceptable providing the below criteria are achieved:

• FOAMGLAS® INVATHERMTM is installed over the waterproofing layer with tight butted joints

• FOAMGLAS® INVATHERMTM is covered by a Water Flow Reducing Layer (WFRL)

• The pedestals must be certified for reaction to fire performance as either Euroclass ‘A1’ or A2’ in conformance with EN 13501

• The pedestal products must have a circular base with a diameter of at least 170mm and be supported by a rubber underlayment as prescribed in the FOAMGLAS Technical Data Sheet, such as Buzon A-PED-107-142 Adjustable Pedestal installed on Buzon U-pad 200 x 200 x 6mm.

• The maximum load indicated in the Product Data sheets is not exceeded.

CERTIFICATES

ISO 9001:2008 Quality Management System, ISO 14001:2004 Environmental Management System, ISO 14025/EN 15804 Environmental Product Declaration, BS EN 13501-1 Reaction to Fire Classification.

FIRE PERFORMANCE

As a roofing system for roofs, roof terraces, enclosed balconies over heated space and insulated walkways

In accordance with Annex of Commission Decision 2000/553/EC, when used in an inverted roof specification including an inorganic covering of either loose laid gravel with a thickness of at least 50mm or a mass ≥ 80 kg/m², sand/cement screed to a thickness of at least 30mm, or cast stone or mineral slabs of at least 40mm thickness a roof system incorporating FOAMGLAS® INVATHERMTM can be considered to be unrestricted under the national Requirements (Classification Broof(t4) to BS EN 13501-5:2016).

As a roofing system component for Specified Attachments such as projecting open balconies, projecting enclosed balconies, recessed open balconies and recessed enclosed balconies

BS EN 13501-1:2016 – FOAMGLAS® INVATHERMTM is certified as achieving Euro Class A1 fire performance by Warringtonfire under reaction to fire classification report No. 19984E.

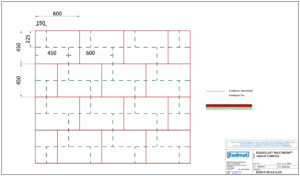

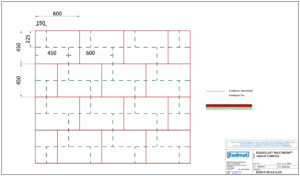

GUIDANCE LAYOUT

Please see Product Data Sheet for full layout guidance instructions