DESCRIPTION

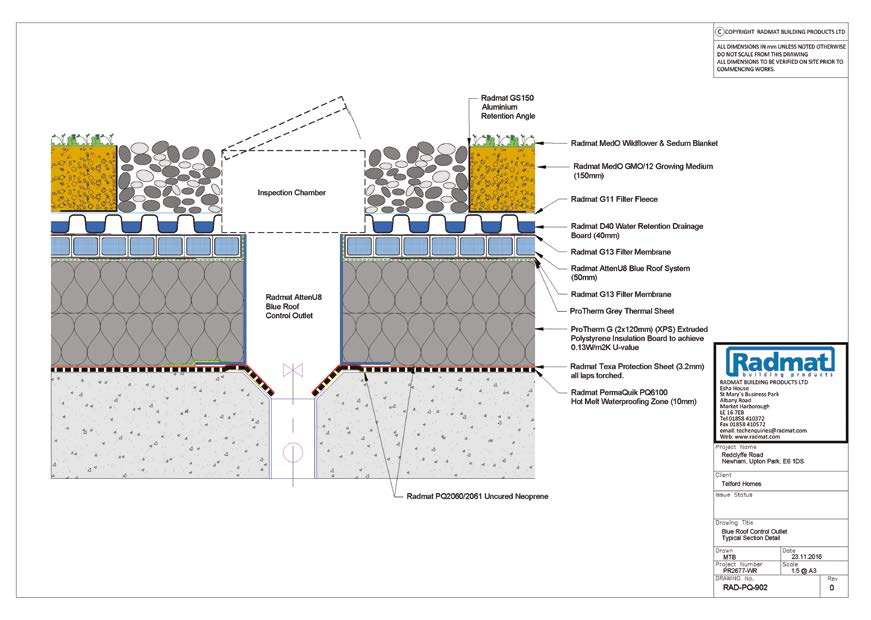

ProTherm G XPS X 500 SL inverted roof insulation is a rigid, closed cell type Extruded polystyrene board with integral high density skin. ProTherm G XPS X 500 SL inverted roof insulation has a Zero Ozone Depletion Potential (ODP), a Global Warming Potential (GWP) of less than 5 and an A rating in accordance with the Green Guide to Specification. For use with Inverted Roof Waterproofing such as PermaQuik PQ 6100, EshaFlex, EshaUniversal, ParaFlex FD and ReadySeal.

SUITABLE APPLICATIONS

ProTherm G XPS X 500 SL is suitable for use in roofs, roof terraces, enclosed terraces over heated space and insulated walkways in an inverted roof construction. When used in the inverted roof constructions listed in the Fire Performance section below roof constructions incorporating ProTherm G XPS X 500 SL achieve Broof(t4) Classification to BS EN 13501-5 as required by Approved Document B 2019 edition, Section B4, Limitations on roof coverings.

ProTherm G XPS X 500 SL is not suitable for use in inverted roof applications on specified attachments such as projecting open balconies, projecting enclosed balconies, recessed open balconies or recessed enclosed balconies.

ProTherm G XPS X 500 SL is not suitable for use in warm roof applications (where the waterproofing is installed above the insulation board).

CERTIFICATES

ISO 9001@2015 Quality Management System, ISO 14001:2015 Environmental Management System, EPD as per ISO 14025 and EN 15804.

DURABILITY

The product will have a life of at least 25 years under normal circumstances.

FIRE PERFORMANCE

As a roofing system for roofs, roof terraces, enclosed terraces over heated space and insulated walkways

In accordance with Annex of Commission Decision 2000/553/EC, when used in an inverted roof specification including an inorganic covering of either loose laid gravel with a thickness of at least 50mm or a mass ≥ 80 kg/m², sand/cement screed to a thickness of at least 30mm, or cast stone or mineral slabs of at least 40mm thickness a roof system incorporating ProTherm G XPS X 500 SL can be considered to be unrestricted under the national Requirements (Classification Broof(t4) to BS EN 13501-5:2016).

Hexabromocyclododecane (HBCD) was phased out prior to the 21st August 2015.