DESCRIPTION

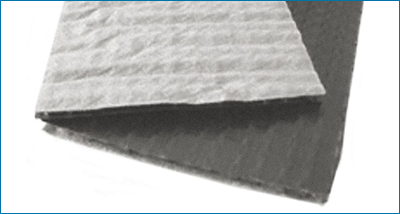

ProTherm XPS X MK Water Flow Reducing Layer is a spun bonded polyethylene geotextile based upon Tyvek® by DuPont that is waterproof and vapour permeable.

ProTherm XPS X MK Water Flow Reducing Layer replaces the usual separating layer laid between the insulation and ballast, prevented water from reaching the waterproofing layer and almost completely eliminating the rainwater cooling effect.

When installed with ProTherm Quantum inverted roof insulation in an inverted roof ProTherm XPS X MK Water Flow Reducing Layer reduces the rainwater cooling, reducing the required insulation thickness by 2%.

Available in 100m roll length, ProTherm XPS X MK Water Flow Reducing Layer is for use with inverted roof waterproofing such as PermaQuik PQ6100, EshaFlex, EshaUniversal and ParaFlex.

For a comprehensive NBS J31 specification contract Radmat Building Products.

APPLICATION

Lay ProTherm XPS X 300 ULTRA/ProTherm G XPS X 300 SL.

Unroll and loose lay over the insulation, unrolling across the slope/direction of fall at the bottom of the slope next to the parapet wall or upstand.

Overlap the next roll by 300 mm creating an unsealed overlap joint in the downward direction of the roof slope/fall. When doing runs longer than the roll offset the 300mm wide end laps roll to roll in a brick bond fashion.

Temporary ballast as you go, checking the side and end laps remain at 300mm wide.

Cut separate strips for use at upstands and penetrations. Cut with scissors and take care not to damage the ProTherm XPS X 300 ULTRA/ProTherm G XPS X 300 SL insulation. Ensure the strips are wide enough to provide a 300mm overlap onto the flat roof at the base and high enough to terminate at the level of the finishes. At the bottom of the slope/fall tuck beneath the first flat sheet installed.

At drainage outlets star cut the WFRL and turn down into the insulation board.

At square or rectangular penetrations cut strips of WRFL wide enough overlap 300mm beneath the flat WRFL and reach the level of the finishes.

At soil vent pipes or round penetrations, the 300mm base of the WFRL should be star cut and tucked beneath the flat WRFL.

A separate piece of WFRL should then wrap the pipe to the height of the finished to aid continuity.