Radmat Building Products has supplied a comprehensive range of systems for the retrofitted Bracken House in the City of London, for The Financial Times, designed by JRA Architects for McClaren’s Construction. Radmat’s PermaQuik, ParaFlex and EshaFlex waterproofing systems with ProTherm Quantum PLUS+ and XPS Insulation have been installed during the refurbishment of the building, which includes a unique pizza-shaped roof design, offering spectacular views over the Capital, including St. Paul’s Cathedral and the Shard.

The Grade II listed refurbishment was not without its challenges for Partnering Contractors and Radmat. Situated in the City of London next to St Paul’s Cathedral, the team had to keep within a v3mm tolerance in order to meet the strict conservation height restrictions to preserve St Paul’s skyline.

Furthermore, the original warm roof was inaccessible, and so had to be stripped out. The works involved stripping the existing single ply and removing the insulation and VCL, before laying the Radmat PermaQuik Hot Melt Monolithic Membrane directly to substrate. Due to the proximity to St. Paul’s Cathedral, there was limited height available for insulation on this extensive refurbishment. To meet the required 0.18W/m2K U-value within the existing 75mm insulation zone, ProTherm Quantum PLUS+ Hybrid was used with ProTherm Quantum PLUS+ Pure over the existing concrete plinths. This ensured the FFLs stayed within the conservation restrictions required. ProTherm XPS Infill was used to fill in the gaps and had to be hot wire cut so there was no stray insulation. The Quantum Insulation also had to be protected with ply wood so it wasn’t damaged or blown away. It was essential that the neigbouring buildings and the street level were protected.

The team also had to plan the logistics meticulously on this central London site, using hoists to transport materials to the roof.

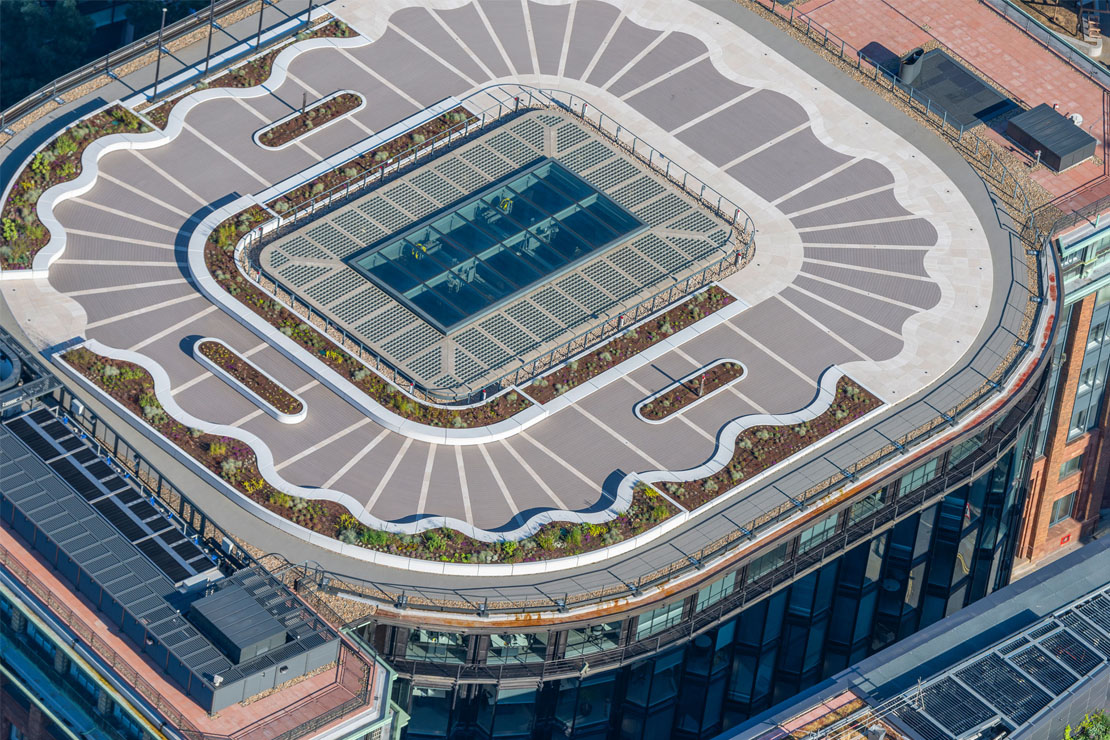

An inverted hot melt system was used to create the multi-purpose roof garden, comprising break out areas, planters and a 150m roof-top running track. These had to be waterproofed to ensure no damage would leak through to the new roof. Radmat’s PermaQuik and EshaFlex systems were used with the peace of mind afforded by a ‘design-life of the building‚ guarantee to make sure this would not occur.

No concrete could be used on the running track due to fracturing, so the roof was constructed in a pizza shape to allow for the segmentation. FOAMGLAS® was also used in these areas to ensure the roof had the compressive strength it needed.

The inverted roof required new water chutes and copper gutters (as the existing ones had become too fragile) to avoid pooling. These were protected with ParaFlex cold applied waterproofing membrane.